Have any questions?

+44 1234 567 890

Backlight inspection system for detecting microtears in deep-rawn aluminum or laminated foil materials and in aluminum foil.

Pin Hole Detector EOK CR

Backlight inspection system EOK-CR designed for detecting microtears in deep-drawn aluminum or laminated foil materials and in aluminum foil before filling process.

The formed aluminum laminate is illuminated by a specially designed row of LEDs. Highly sensitive sensor elements in the receiver register light passing through a tear. If the Tear Detection Unit recognizes the presence of a tear when evaluating the signal, it indicates this visually on the device front panel and sets the appropriate outputs. Constant illumination over the full width of the scanning field is assured through the use of special high-constancy transmitter modules. The new, completely revised version is microcontroller-controlled and provides easy operation and additional functions. The measurement range is set by using a keypad. All parameters can be displayed on a two-line display. You can also transfer statistical data via a serial port using a PC.

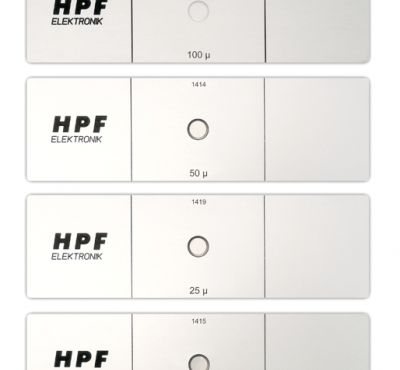

The device is self-monitoring, i.e. if a transmitter fails, the „ready-to-operate“ status display disappears and the internal relay drops out. The transceiver elements together with the evaluation electronics are housed in a compact, highly rugged aluminum case. The Tear Detection Unit is suitable for retrofitting in most machines due to its compact dimensions. The transmitter is directly secured to the foil guideway by two fastening bolts as standard, with the receiver secured beneath it. For light transmission, a slot must be milled across the full width of the scanning field transverse to the foil transport direction. A stabilized 24 VDC power supply is required to avoid malfunctioning or damaging the electronics. A suitable 230 VAC/24 VDC power supply unit is included in the scope of supply.The precision lithographic made calibration gauges are used to check the configuration of the Tear Detection Unit for specific tear sizes. A 100 μm calibration gauge is included in the scope of supply. This size is set by default in most cases. Additional matrices for special applications can be supplied in sizes ranging from 5 to 140 μm. With a highly sensitive setting, the unit will reliably detect tears down to 5 μm.

TECHNICAL DATA

Service Description

- Tear detection down to 5 μ

- Very easy to operate

- Unit is self-monitoring

- Several standard sizes available

- Available calibration gauge sizes: 5, 10, 25, 35, 70, 100 und 140 μm

- Statistics can be evaluated by PC

- Typical foil width: 100 to 600 mm, special design on request

- Also suitable for retrofitting

Accessories

- Calibration gauges for sensitivity adjustment: Lithographic made stainless steel foil, mounted in aluminum holder, available hole sizes 5, 10, 25, 35, 50, 70, 100, and 140 μm.

- Shift register, standard Eurocard (5 U) for signal propagation, up to 100 machine operating cycles for 8 blister packing lines, with special functions.

Standard widths

| Type | Scanning field width | Case width |

|---|---|---|

| EOK-CR 200 | max. approx. 140 mm | 200 mm |

| EOK-CR 280 | max. approx. 200 mm | 280 mm |

| EOK-CR 320 | max. approx. 220 mm | 320 mm |

| EOK-CR 380 | max. approx. 260 mm | 380 mm |

| EOK-CR 420 | max. approx. 320 mm | 420 mm |

| EOK-CR 430 | max. approx. 360 mm | 430 mm |